The Fuel Tank - Phase 3: The Template

Phase 3: Creating the Laser Cut Template

With the file ready, we started to laser cut the template with 2.6 mm gap.

We then attempt to put the pieces together

However we found that 2.6 mm gap is too tight for the whole template, we found it worked for the test we did as it was just a small piece, with the fuel tank template however, we found that the bigger the piece is the harder it is to fit. We learned that 2.6 mm results in no tolerance, which results in the pieces began to split and snap as we tried to fit them in.

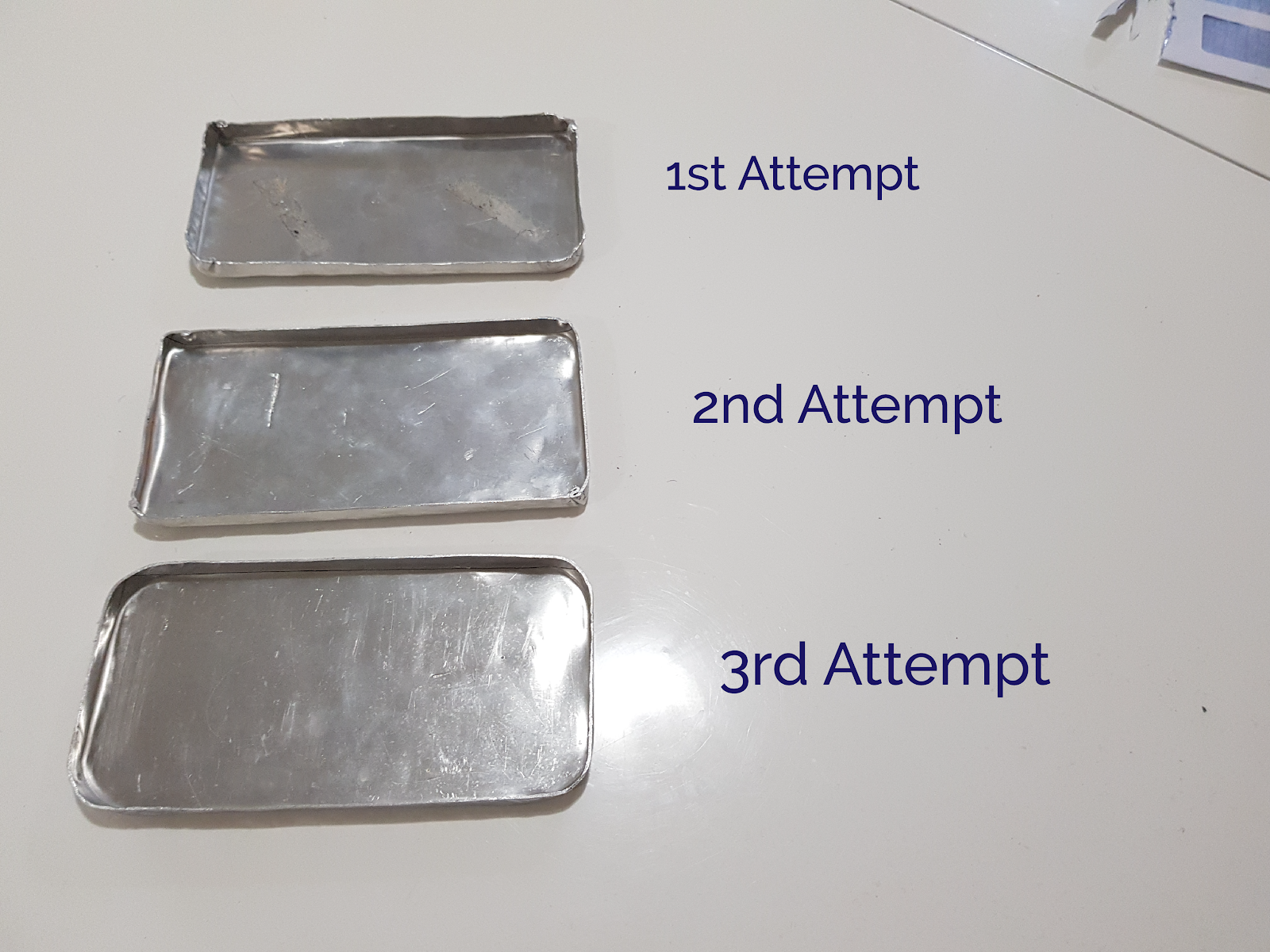

Our failed attempt (sad reacts only)

Daniel suggested that we are better off with the material thickness of 3 mm or even 3.5 mm for the gap, yes it would be wiggly but we can use glue gun to solidify it.

Our 2nd attempt we did just that; laser cut a template with 3.5 mm gap and assemble it using glue gun to stick the pieces together

Comments

Post a Comment