The Fuel Tank - Phase 1: Planning

THE FUEL TANK

Our next assignment was to create a 1:1 scale fuel tank out of aluminium using the techniques learnt from assignment 1. We were to chose one tank from three different motorbikes; Harley 883 Iron, Yamaha IT250, and a Custom tank for a CB550 by Andrew Wallace. We worked in a group of people from different discipline.

Our group decided to go with the Custom tank for a CB550 by Andrew Wallace

Our group name is Kloud 9, consisting of nine multidisciplinary members:

- Yu Jin Son - Industrial design

- Kelvin Ip - Architecture

- Benjamin Le - Industrial Design

- Natalia Dou - Interior Architecure

- Tauqir Ullah - Industrial Design

- Lornia Shi - Industrial Design

- Zoey Song - Interior Architecture

- Zeran Wang - Industrial Design

Phase 1: Planning

We held our first meeting during the class of when the assignment was introduced (18/04/2018), we mainly spend the time getting to know each other and finding out everyone's availability before discussing on how to start the assignment. We didn't have much progress on our first meeting however we held another group meeting on 24/04/2018.

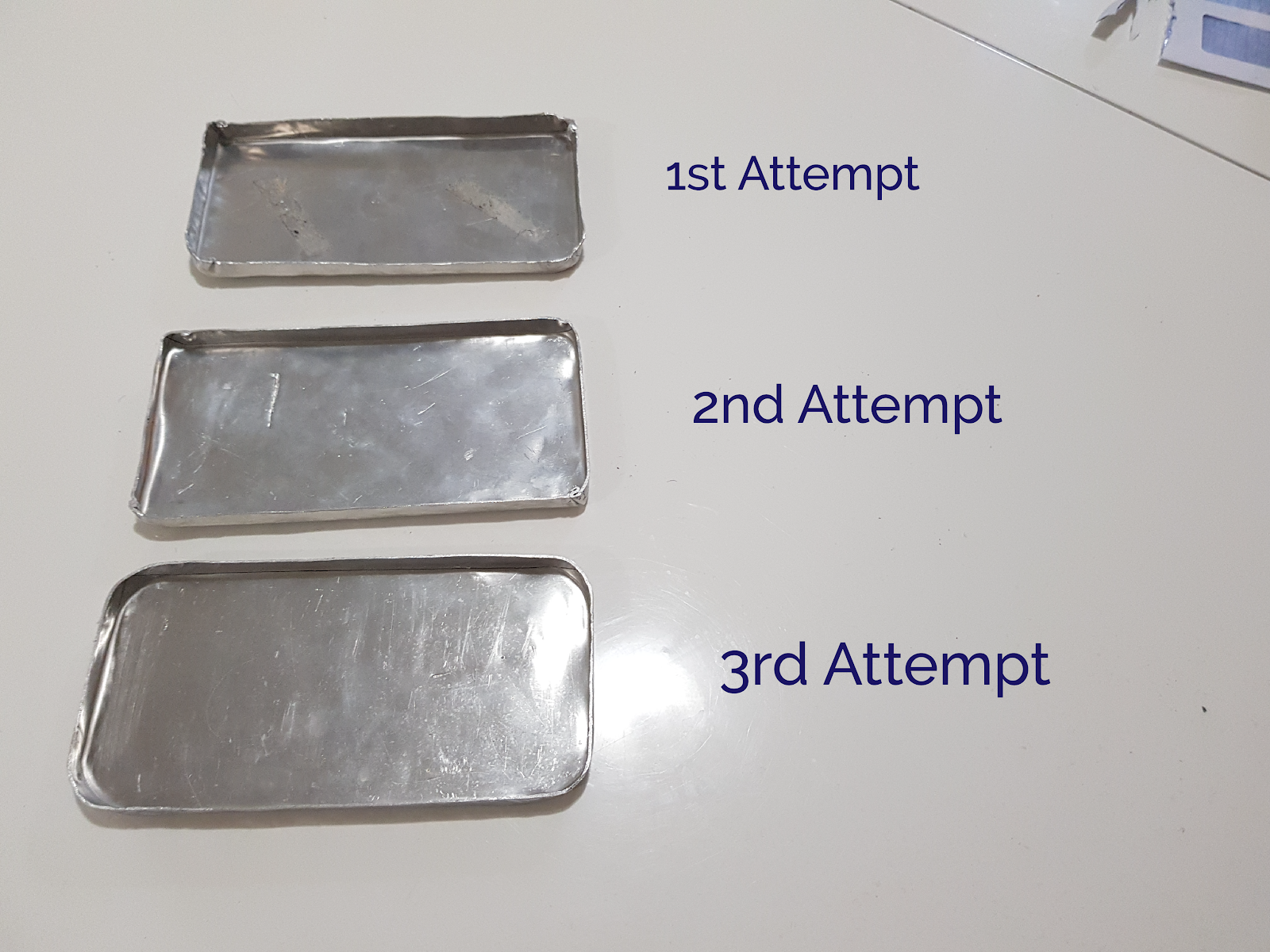

In our 2nd meeting, we assigned each other tasks to research the different methods we could approach the metal forming phase, three of us looked into laser cutting template (the method that was thought in class), another looked into CNCing a mold to metal form onto,and Ben and I looked into how we can make a male mold by hand.

After researching however we ended up with the first method; laser cutting a template, as CNC is too expensive and the height of the tank might be an issue,and making a mold by hand require more time and work and needs to be precise as well as more money.

At the end of the day we decided to laser cut the template the next week, and came up with a plan

Week 9: Complete template

Week 10: Metal forming

Week 11: Metal forming

Week 12: Due

We Decided that the next step is to prepare the file for laser cutting

In our 2nd meeting, we assigned each other tasks to research the different methods we could approach the metal forming phase, three of us looked into laser cutting template (the method that was thought in class), another looked into CNCing a mold to metal form onto,and Ben and I looked into how we can make a male mold by hand.

After researching however we ended up with the first method; laser cutting a template, as CNC is too expensive and the height of the tank might be an issue,and making a mold by hand require more time and work and needs to be precise as well as more money.

At the end of the day we decided to laser cut the template the next week, and came up with a plan

Week 9: Complete template

Week 10: Metal forming

Week 11: Metal forming

Week 12: Due

We Decided that the next step is to prepare the file for laser cutting

Comments

Post a Comment